As a food handler, it is essential to apprehend right food protection practices when cooking and cooling cooked meals like ham.

No longer following accurate tactics can allow micro organism to grow to dangerous tiers, probably causing contamination. This newsletter will outline the stairs a food handler ought to take to cook dinner ham effectively and unexpectedly cool it to save you micro organism increase.

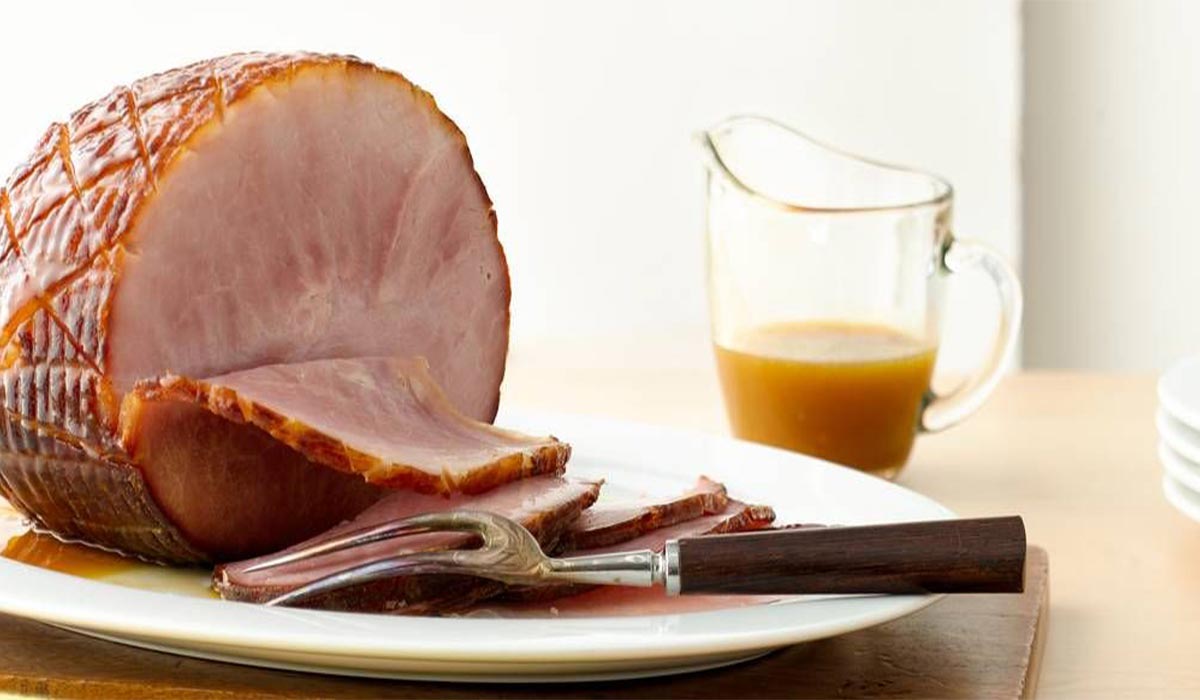

Methods for Cooking Ham

There are a few common methods for cooking ham as a food handler:

Baking:

Bake uncovered in a 325°F oven. Test the inner temperature with a meals thermometer until it reaches one hundred forty five.

Smoking:

For smoked hams, preserve an internal temperature of at the least one hundred forty five

°F at some point of smoking. Check temperature in the thickest part of the ham.

Steaming:

Place ham on a rack set in a pan with 1-2 inches of simmering water. Cover and heat until thermometer shows an internal temperature of at least 145°F.

proper cooking is crucial, because it increases the internal temperature excessive sufficient to kill capability bacteria like Salmonella or Listeria. usually use a food thermometer to make certain the ham reaches one hundred forty five °F.

Maintain at this temperature for as a minimum 15 seconds earlier than doing away with from warmness. Be sure to save you move infection at some point of cooking among the raw ham and other meals.

The Critical Cooling Process

After cooking ham properly, rapid cooling is vital to prevent bacteria growth in the “danger zone” between 40-140°F. The table below shows safe cooling methods:

Cooling Method Time to Reach 70°F

Ice water bath <2 hours

Refrigerator <4 hours

Dividing into small portions <6 hours

For example, a food handler cooks ham and correctly cools it by placing large portions in an ice water bath, stirring occasionally until internal temperature hits 70°F, then storing in the refrigerator. It’s important to verify cool temperatures by checking with a food thermometer.

Food Safety Checks During Cooling

While cooling ham, a food handler must follow these food safety steps:

Tightly wrap ham in plastic wrap or foil for rapid heat transfer during cooling. This is critical for proper cooling.

Label ham package with cooking/cooling dates and “consume by” date.

Ensure cooling and storage areas are cleaned and sanitized per health code.

Take refrigerator temperature daily to ensure it’s at or below 40°F. Bacteria thrives in temperatures between 40-140°F.

By following these cooling steps, a food handler cooks ham and correctly cools it within the required time limits, minimizing risk of bacteria growth like Salmonella. Always practice proper temperature control and food safety.

Frequently Asked Questions

What method should the food worker use to thaw the ham safely?

Cold water thawing.

What ready to eat TCS food that was prepped by a food handler on Monday for use on Wednesday?

Must have a label that includes the name of food and use by date.

When checking a food’s temperature, a food handler should monitor the thermometer until the reading?

When checking a food temperature, a food handler should monitor the thermometer until the reading becomes stable. The stability of the reading may vary depending on the type of food thermometer.

Where should a food handler check the temperature of food?

The most internal part or thickest part of a food.

What is the food safety for ham?

Raw ham must reach an internal temperature of 145°F (63°C) (with a three minute rest time.

Conclusion

Cooking ham to the proper internal temperature before rapidly cooling is crucial for food safety as a food handler.

Using proper handling, cooling methods, and food safety checks prevents bacteria growth and potential foodborne illness. Remember to follow these steps each time to cook ham and correctly cool it.